How to Reduce Packaging Costs Without Compromising Quality

1. Audit Your "Air" (Right-Sizing)

The most expensive thing you can ship is air. Carriers use Dimensional Weight (DIM weight) to calculate shipping costs, meaning they charge based on the volume of the package, not just its physical weight.

The Strategy:

- Custom Tooling: Instead of using standard "Stock" sizes that require handfuls of bubble wrap to fill the void, invest in custom-sized boxes tailored to your top-selling products.

- Multi-Depth Boxes: Use boxes with pre-scored intervals. This allows you to fold the box down to the height of the product, effectively creating three or four box sizes out of one SKU.

2. Rationalize Your Materials

Are you using a triple-wall corrugated box for a product that weighs two pounds? You might be "over-specifying."

How to Optimize:

- The Edge Crush Test (ECT) vs. Mullen Test: Most businesses default to heavy-duty boxes because they "feel" safer. However, switching from a 32 ECT to a 29 ECT board can save 5–10% in material costs without a noticeable drop in stacking strength for lighter goods.

- Standardize Your SKUs: If you have 20 different box sizes, you’re likely paying a premium for low-volume orders. Reducing your library to 5 versatile sizes allows you to buy in bulk, triggering significant volume discounts.

3. Rethink Your In-Box Protection

Bubble wrap is a classic, but it’s bulky to store and expensive to buy. High-quality protection doesn't always mean plastic.

Cost-Effective Alternatives:

- Automated Paper Systems: Paper crumplers create high-volume void fill on demand. While there is an upfront cost for the machine, the "cost-per-cubic-foot" of paper is often lower than plastic air pillows or foam.

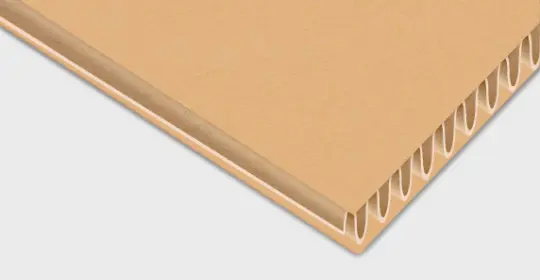

- Corrugated Inserts: Instead of loose-fill (which shifts during transit), use custom die-cut corrugated inserts. They lock the product in place, use less material, and provide a premium "unboxing" feel.

4. Don't Sleep on Corrugated Substitutes

Not every product needs a box. In fact, boxes are often the least efficient way to ship soft goods.

The Pivot:

- Poly Mailers & Padded Envelopes: If you are shipping apparel, bedding, or soft goods, swap the box for a high-strength poly mailer. You’ll save on the material cost (pennies vs. dollars) and drastically reduce the DIM weight.

- Eco-Friendly Mailers: With the 2026 sustainability mandates, compostable or 100% recycled paper mailers are now price-competitive with traditional plastic, helping you save money and "green" your brand image simultaneously.

5. Optimize the Packing Process (Labor Costs)

Packaging costs aren't just about the physical box; they are about the time it takes to pack that box.

|

Feature |

Time to Pack |

Cost Impact |

|

Manual Taping |

25-40 seconds |

High Labor |

|

Auto-Bottom Boxes |

3-5 seconds |

Low Labor |

|

Water-Activated Tape |

15-20 seconds |

Medium Labor / High Security |

The "Total Cost of Ownership" Approach:

An "Auto-Bottom" box might cost $0.10 more per unit, but if it saves your warehouse team 30 seconds per package, the labor savings far outweigh the material increase.

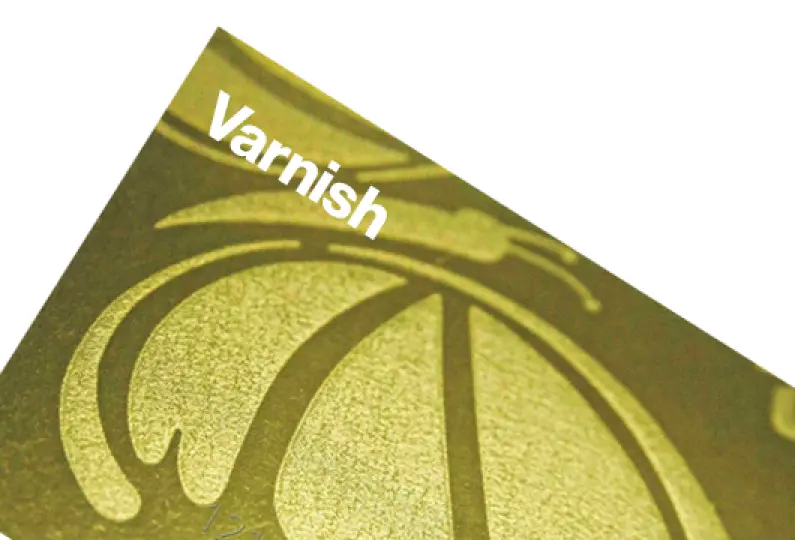

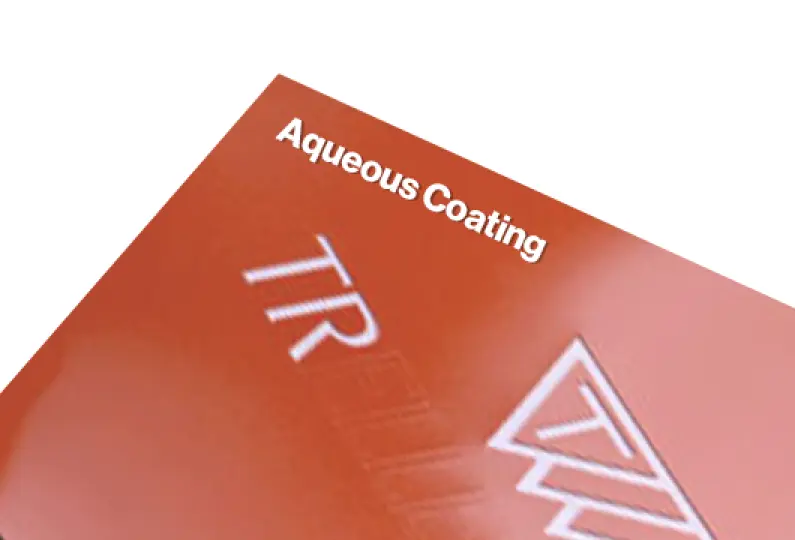

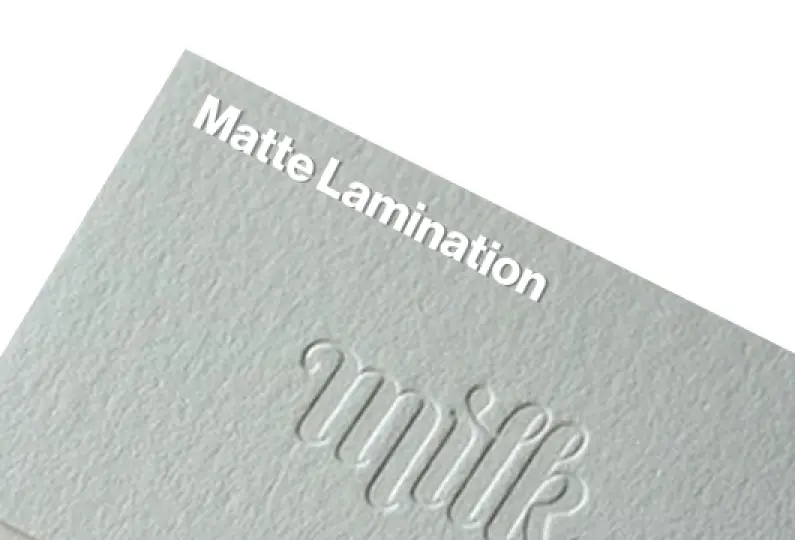

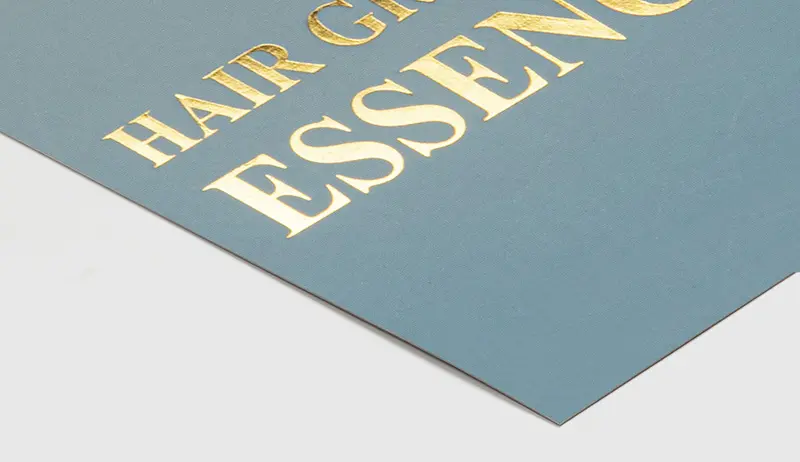

6. Leverage "Blind" Branding

Everyone wants a full-color, high-gloss printed box. But the tooling and ink costs for digital or flexographic printing can be astronomical for small to mid-sized runs.

The Pro Move:

- Exterior vs. Interior: Keep the outside of the box plain (which also reduces the risk of "porch piracy") and print a "thank you" or brand story on the inside.

- Custom Tape & Stickers: Use a standard kraft box and brand it with high-quality custom gummed tape or a large-format sticker. It provides the same brand recognition at a fraction of the cost of custom-printed corrugated board.

7. Damage is the Ultimate Cost

The most expensive package you will ever ship is the one that arrives broken. A "cheap" packaging solution that results in a 5% increase in damage claims is actually a financial disaster.

Calculate the "True Cost" of Damage:

Total Loss = Cost of Product + Shipping Out + Shipping Return + Customer Acquisition Cost

If reducing your packaging quality leads to even a small uptick in returns, you aren't saving money but you're losing it. Always perform a Drop Test (ISTA standards) before committing to a cheaper material.

8. Negotiate Through Your Partner

Many businesses try to source packaging disjointed, buying tape from one vendor, boxes from another, and labels from a third.

The Benefit of Consolidation:

By partnering with a full-service packaging provider, you gain access to:

- Vendor Managed Inventory (VMI): We hold the stock so you don't waste expensive warehouse floor space.

- Freight Consolidation: We ship your materials together, reducing the "hidden" cost of inbound shipping.

Conclusion: Strategy Over Skimping

Reducing packaging costs isn't about buying the thinnest cardboard possible. It’s about engineering. By right-sizing your containers, standardizing your SKUs, and valuing labor efficiency as much as material costs, you can protect your bottom line as effectively as you protect your products.

Stop paying for air and start paying for performance.