Corrugated Packaging vs. Rigid Packaging: Which to Choose for Your Business?

In the dynamic world of packaging, making the right choice between corrugated and rigid materials can significantly impact your product's safety, presentation, sustainability, and ultimately, your bottom line. Both offer distinct advantages and are suited for different applications, making an informed decision crucial for any business. This comprehensive guide will delve into the nuances of corrugated and rigid packaging, helping you determine which is the optimal choice for your specific needs.

Understanding Corrugated Packaging: The Workhorse of Shipping

Corrugated packaging, often simply referred to as "cardboard," is a ubiquitous material in the shipping and e-commerce industries. Its strength, versatility, and cost-effectiveness make it a go-to for protecting goods during transit.

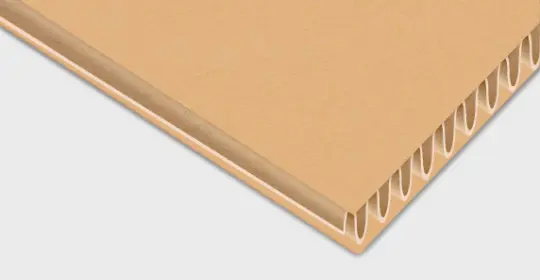

What is Corrugated Packaging?

Corrugated material is essentially a fluted (wavy) sheet of paper, known as the medium, sandwiched between two flat linerboards. This multi-layered structure creates a series of arches that provide exceptional rigidity and cushioning against impacts. The number of flutes, their size, and the type of paper used all contribute to the strength and performance of the final corrugated board.

Types of Corrugated Flutes:

- A-flute: The largest flute, offering excellent cushioning and stacking strength. Ideal for fragile items.

- B-flute: A smaller flute, providing good puncture resistance and crush strength. Often used for retail displays and canned goods.

- C-flute: The most common flute size, balancing cushioning, stacking strength, and printability. Suitable for a wide range of products.

- E-flute: A very fine flute, offering a smooth surface for high-quality printing and often used for consumer goods packaging.

- F-flute: The finest flute, primarily used for very small boxes and retail applications where aesthetics are paramount.

Beyond single-wall corrugated, you can also find double-wall (two flutes and three linerboards) and triple-wall (three flutes and four linerboards) options, offering progressively higher levels of strength for heavy or extremely fragile items.

Advantages of Corrugated Packaging:

- Strength and Protection: The unique fluted structure provides excellent shock absorption and resistance to crushing, protecting products from damage during shipping and handling.

- Cost-Effective: Corrugated materials are generally more affordable to produce and purchase compared to rigid packaging, especially for bulk orders.

- Lightweight: Despite its strength, corrugated packaging is relatively lightweight, which helps reduce shipping costs.

- Versatility: It can be easily cut, folded, and shaped into a vast array of box styles, inserts, and displays, making it adaptable to almost any product.

- Printability: While traditionally known for its brown kraft appearance, corrugated can be printed with high-quality graphics and branding, especially on E and F flutes, allowing for effective marketing.

- Sustainability: Made primarily from renewable resources (wood pulp) and often containing a high percentage of recycled content, corrugated packaging is highly recyclable and biodegradable.

- Stackability: Its inherent strength allows for efficient stacking in warehouses and during transit, optimizing storage space.

Disadvantages of Corrugated Packaging:

- Aesthetic Limitations (Traditional): While printing has improved, traditional corrugated may not always convey the same sense of luxury or premium quality as rigid packaging.

- Susceptibility to Moisture: Uncoated corrugated can weaken significantly when exposed to moisture, though coatings and laminations can mitigate this.

- Less Premium Feel: For high-end luxury products, the perception of corrugated might not align with the brand image, even with high-quality printing.

Ideal Applications for Corrugated Packaging:

- E-commerce shipping boxes

- Subscription boxes

- Food and beverage packaging (especially for bulk or processed items)

- Electronics and appliances

- Retail ready packaging (RRP)

- Industrial parts and components

- Moving and storage boxes

Here's an example of a typical corrugated box:

Understanding Rigid Packaging: The Epitome of Premium Presentation

Rigid packaging, often referred to as "set-up boxes" or "luxury boxes," stands at the opposite end of the spectrum from corrugated in terms of perception and construction. It's designed to make a statement, convey exclusivity, and offer a premium unboxing experience.

What is Rigid Packaging?

Rigid packaging is constructed from highly compressed paperboard or chipboard, which is typically four times thicker than the paperboard used in folding cartons. Unlike corrugated, rigid boxes are usually pre-assembled and do not fold flat. They are wrapped with decorative paper, fabric, or other materials, creating a seamless and sophisticated finish.

Types of Rigid Box Constructions:

- Full Telescope: The lid fully covers the base, offering maximum protection and a sleek appearance.

- Partial Telescope: The lid covers only a portion of the base, allowing for a contrasting visual element.

- Shoulder Box: A tray-like base and lid meet at an inner "shoulder" piece, creating a distinctive two-piece look.

- Book Style: Resembles a hardcover book, opening to reveal the product inside.

- Drawer Style (Slide Box): Features an inner tray that slides out from an outer sleeve.

Advantages of Rigid Packaging:

- Premium Aesthetics and Feel: Rigid boxes inherently exude luxury, sophistication, and high quality. The smooth, seamless surface and robust construction elevate brand perception.

- Enhanced Protection: The thick, rigid construction offers superior protection against crushing, impacts, and external pressures, safeguarding delicate or valuable products.

- Durability: Rigid boxes are built to last, often being kept by consumers for storage, further extending brand exposure.

- Exceptional Unboxing Experience: The sturdy feel, potential for intricate designs, and often magnetic or ribbon closures contribute to a memorable and positive unboxing experience, crucial for luxury brands.

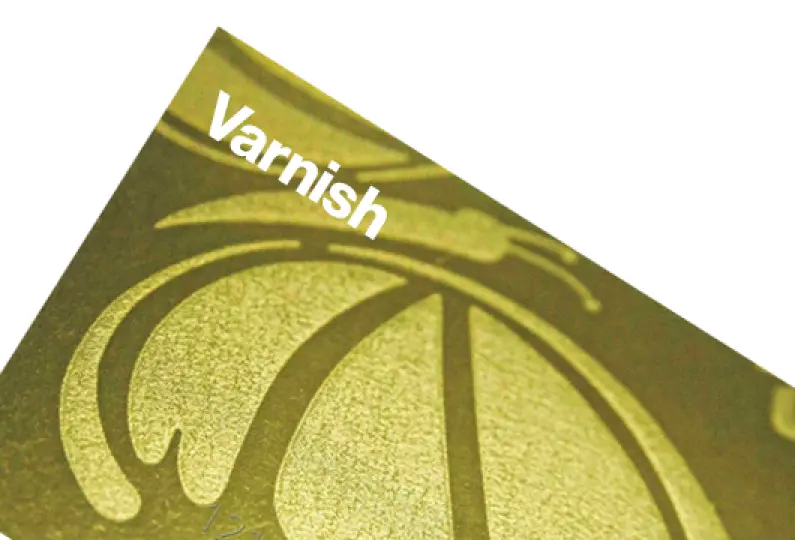

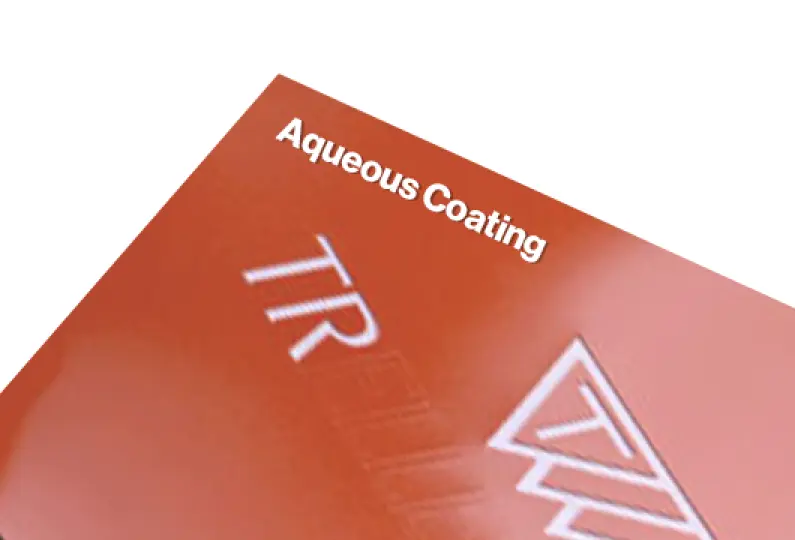

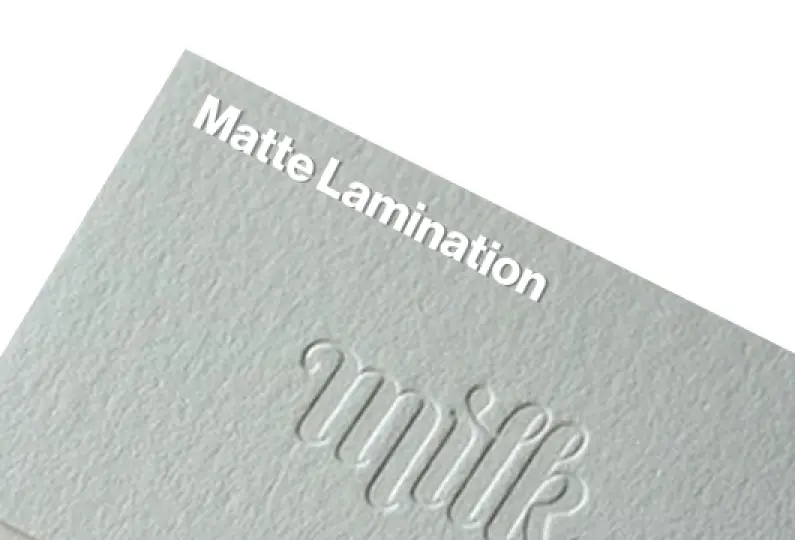

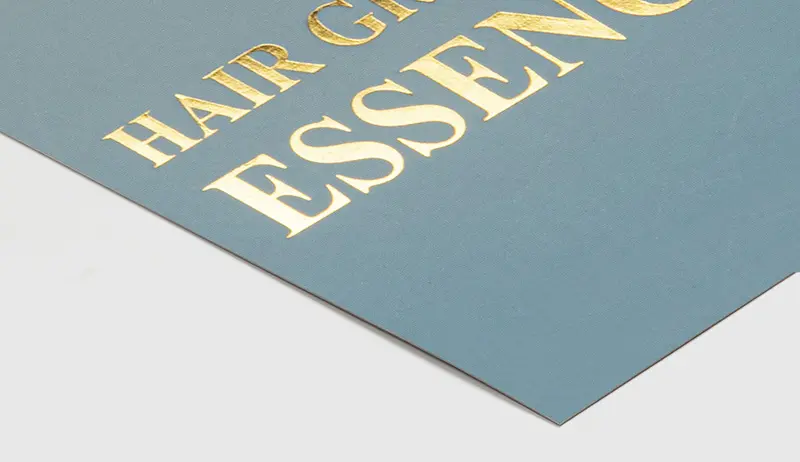

- Versatility in Finishing: Rigid boxes can be customized with an extensive array of finishes, including embossing, debossing, foil stamping, spot UV, laminations, and custom inserts, allowing for unparalleled branding.

- Strong Brand Storytelling: The tactile experience and visual appeal of rigid packaging offer a powerful canvas for brand storytelling and reinforcing brand values.

Disadvantages of Rigid Packaging:

- Higher Cost: Due to the materials, labor-intensive manufacturing process, and specialized finishing techniques, rigid packaging is significantly more expensive than corrugated.

- Larger Storage Footprint: Unlike corrugated boxes that ship and store flat, rigid boxes are pre-assembled, requiring more storage space in warehouses and during shipping before product fulfillment.

- Heavier Weight: The dense material makes rigid boxes heavier, which can increase shipping costs, especially for large volumes.

- Less Sustainable (Historically): While efforts are being made, the multi-material construction and often non-recyclable coatings or laminations can make rigid boxes less straightforward to recycle compared to corrugated. However, many manufacturers are now focusing on sustainable rigid packaging solutions.

Ideal Applications for Rigid Packaging:

- Luxury goods (jewelry, watches, high-end cosmetics, perfumes)

- Electronics and gadgets (smartphones, premium headphones)

- High-end apparel and accessories

- Gourmet foods and confections

- Promotional kits and corporate gifts

- Collector's editions and limited-run products

- Any product where perceived value and brand experience are paramount.